Take a breath, sit back and think: Why the fuck not spend some money instead of endless, painful hours? You don’t have money ok, ok, but what if you… WAIT. Wow, a new world, 3D printing, ACTUAL 3D printed hollow cubes that I PRINTED. Oh wait, is that smoke?

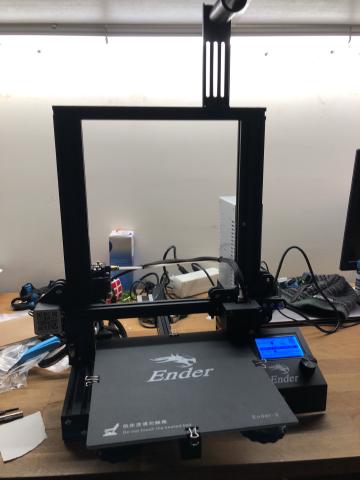

Welcome ladies and gentlemen on another miserable and painful part oooooof drumroll the CHINESE FACTORY!!! Starring: - Tears - Anxiety - A Creality Ender 3 3D Printer kit that I got from gearbest - 1 month waiting - Smokey electronics

This time, once again, I thought I knew, that I learned from my mistakes. If you don’t know what I’m talking about, check this out. It was time to buy my first, whole, 3D printer kit. Backed by a very big community, Ender 3 by Creality was a very good shot. Everyone was astonshed by the results that this baby could achieve. Medium printing speed, medium noise, but the object was very nice. I also ordered with it TWO BlTouch clones. Not one (cause I knew), but TWO. Noice.

I saw a couple youtube videos, just to be sure and get some tips, but the build process was pretty simple. They nagged that it lacked a step or two or a screw, but with my experience on the Rostock Mini and the Prusa i3, I couldn’t even get why they were nagging. I had spares of everything: nuts, bolts, motors, drivers, boards, beds. I was fairly sure that as soon as something goes wrong (cause I was FAIRLY sure about that), I’ll be able to replace it. The device even came pre-flashed! I didn’t even have to fiddle with Marlin! What I was missing all these years…

First prints

After I put everything together, I turn on the machine, I select a pre-sliced model and I hit print. AND IT PRINTS. The bed was a bit off. BUT IT PRINTS. I tried not to cry cause that shithole that I called home would flood in an instant and burn my printer.

Ok, everything works, I level the bed a bit and I fire up Cura for some serious (meh) shit: my first useful model. A little ventring to cool the parts all around the hotend. And it prints it smooth as fuck. I just couldn’t believe it… I had a working 3D printer!

So now, lets mount the BLTouch. I start printing the model, but somehow, I forgot that the silver “ear” of the paper clip holding the bed is open on the left side of the bed. And it gets stuck on the Z axis. And before I know it, the cable connecting the controller to the screen is orange-ish and the controller is smoking a pack of Marlboros…

I turn off everything, I panic and I’m just staring at the black aluminum brick that I had in front of me…

The Controller Fix

I plug the printer again, to see what the damage was: XYZ and the screen were dead. Everything else seemed fine. Thermistors, heaters, extruder, all fine. The screen was completely optional to me, as I ran the printer via USB, so the real problem was XYZ. Debugging was officially in progress…

You can see the “ears” of the clips on the left and right side of the bed - moments before the disaster

I was pretty sure that the stepper controllers were fried. They are fragile and it happens. Problem was that they were soldered on the PCB. BTW, a quick note:

Dear 3D printing community, After I was done panicking and crying over my dead printer, I remembered that I know how to wield a soldering iron. So I found the pinouts of the Creality “Melzi” board and scratched the traces (to expose some copper and solder on it) of

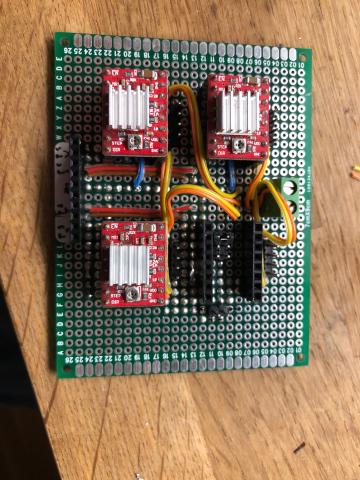

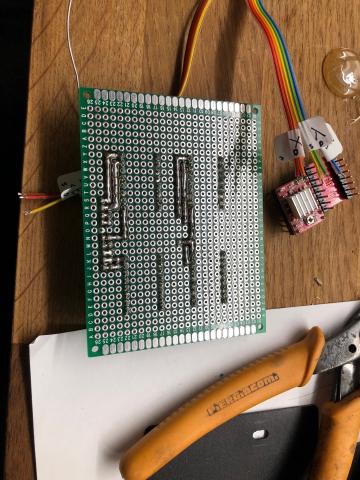

dir&stepto break out the pins and hook them on the backup stepper drivers that I had. I quickly soldered a circuit on protoboard (with solder bridges) to have a nice pinout and hooked the board on it.

Nope, XYZ still dead. Ugh…

The logic analyzer kindly explained to me that the pins coming from the MCU, were dead - this happens when you feed weird stuff to AVR (e.g. over 5v). They don’t die, they give away that specific pin, they are very tough…

Well ok, that’s fine, I had a lot of spare pins in the screen connector, now unused. The idea was to remap the step/dir pins to them. That was fairly easy, as I had hooked the whole lanes from the PCB to the steppers, without cutting any traces. After some pain to understand which screen pin is which, I finally did it :) I changed which MCU pins talk to the stepper drivers.

It was alive :)

The Rabbit Hole Exhaustion

After that incident, about a year passed and I don’t know why I left the printer on the side. I had fiddled with it too much, I did stuff that where not neceserry. I tried to switch to RAMPS 1.4, but had problem with the heating elements not heating enough, even after cutting the D1 diode (spoiler: it was the polyfuse), I switched to klipper from Marlin and broke the printer into two boards etc. etc. I didn’t get to print anything at that point. Always something was problematic and didn’t let me print.

The Slap

About a year passes and I get a girlfriend. I tell her that I have a 3D printer that is currently in an unknown state. She was AMAZED and asked me why I don’t fix it. That was it. That was the slap that I needed to get back in track and fix the damn thing. When a partner gets excited about a nerdy thing you don’t let neither the partner nor the thing go. You just hold on to what you do. Until they orgasm. Or until you orgasm. Or both. Or until you finish the project (lol). Anyway…

I ordered a replacement board. Gearbest gave me $50 off and I got a new official Creality board for about 20mor**e.Kindastupidmoveasthepricewasinsan**e(70 for an arduino with 4 stepper drivers), I know, but I couldn’t get back to the rabbit hole again…

I hook it up, I hook up the BLTouch and BOOM. It works… and unbelievably silent. A quick google search showed that I luckily upgraded to TMC drivers that are extremely silent. The only noise was the fans! Wow…

The Happy Ending

After some playing around and overcoming some difficulties: - G28 negates bed leveling, you need a Marlin setting to fix that - Probe X/Y offset settings are not for fun, the bed mesh is shifted - Teflon tube on the hotend goes ALL the way down to the heatblock - PLA pieces can get into the hotend fan and stop it (and we know what that means) - PLA and PLA+ are not the same - Ender 3 plastic extruder is trash - get the aluminum one - Glass bed with carbon finish is amazing - well worth the 20$ - OctoPrint is quite neat & it can send you image notification on Telegram

The printer was actually fine. It still prints very nicely! I’ve print several stuff for home and the GF even got the handle of tinkercad and designed & printed some stuff!

WhyNot.Fail is not only about fails, but for success stories too, as 99% of the time they include massive failures.